There are many different types of loom, understanding the right type of loom for your project will help to ensure your wiring will last. Using loom is important to protect exposed wires and cables from foreign debris, the harsh environment, and high vibration areas. Some of the different types we will look at are: Split, Non-split, Spiral, Expandable, Braided, Woven, Heat Shrink, Metal, High Temperature and Asphalt. Wire loom will provide protection for your bundles of wire and cable while also keeping your electrical application neat and organized.

Del City offers many types of loom that can be used in multiple applications. Factors that influence your choice will be personal preference and the needs of your application. Read on for a brief explanation to understand some of the most popular different types of loom that Del City offers

Split Loom

Split loom emerges as a highly sought-after wire management solution, renowned for its user-friendly design and affordability. Widely embraced by customers across various industries, its popularity stems from its ease of use and cost-effectiveness. Available in four distinct types – standard PE, high temp nylon, flame retardant, and UV resistant – split loom offers a versatile selection to suit diverse applications and environmental conditions. Each variant features a convenient slit running the entire length, facilitating effortless wire insertion and simplifying installation processes. Crafted from high-quality materials, split loom boasts a unique high-rise-rigid construction that delivers superior flexibility without the risk of kinking or the slit opening unexpectedly. This robust design not only safeguards wires against abrasion but also provides reliable protection against crushing, ensuring optimal performance and longevity. Whether you’re safeguarding automotive wiring or enhancing electrical systems in industrial settings, split loom proves to be an indispensable solution for achieving hassle-free wire management with maximum durability and resilience.

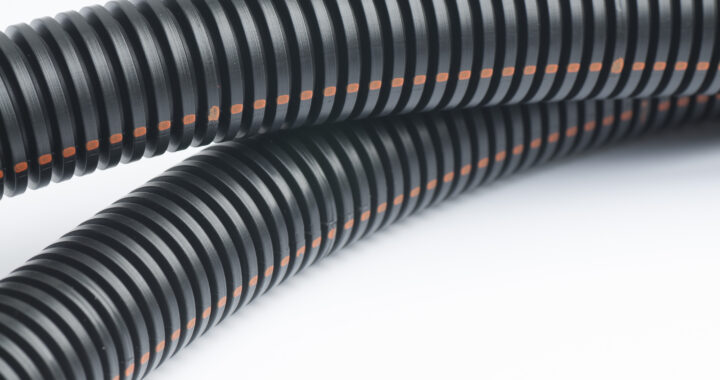

Spiral Cut Loom Type

Spiral cut loom stands out as a distinctive type of wire management solution, highly favored by customers seeking versatility and adaptability in their wiring setups. Its unique design allows wires to be effortlessly pulled out at various points along the run and from different angles, providing unparalleled flexibility and convenience. Whether you’re navigating tight corners or accommodating changes in wiring configurations, spiral cut loom proves to be an invaluable asset in ensuring smooth and efficient installations. Additionally, its popularity extends to applications where retrofitting existing harnesses is required, making it an ideal choice for upgrading and enhancing wiring systems without the need for extensive modifications. With spiral cut loom, you can effortlessly achieve a seamless integration of wires while enjoying the utmost convenience and ease of use. Take a look at our offering of Spiral cut loom.

Expandable Sleeving

This versatile sleeving boasts an impressive ability to expand, typically doubling its inner diameter size, while retaining the capability to contract back to its original size with a secure grip, ensuring wire bundles stay neatly in place and well-protected. With six distinct types available, there’s a perfect match for every application. Our standard PE sleeving, offered in black, red, yellow, and blue, provides a reliable solution for everyday wire management needs. For enhanced safety and peace of mind, our flame retardant sleeving offers added protection against fire hazards. If convenience is a priority, our clean cut sleeving can be easily trimmed with scissors to achieve a precise fit. For applications requiring extra durability and resilience, we recommend our heavy wall, super duty, or flat filament expandable sleeving options. These variants are specially engineered to withstand high levels of abrasion, ensuring long-lasting protection for your wires in demanding environments. Whether you’re working on automotive projects, industrial machinery, or electronics, our expandable sleeving solutions deliver the performance and reliability you need to keep your wire bundles secure and safeguarded against wear and tear. We have a wide variety of expandable sleeving, you can see that here.

Braided Sleeving

Designed for effortless wire management, this innovative sleeving solution boasts a self-wrapping design that securely envelops and encloses wire bundles with ease. Unlike traditional split loom, this sleeving offers enhanced flexibility, allowing for seamless insertion and removal of wires without compromising on durability. Crafted from premium materials, the braided construction of this sleeving ensures superior flexibility and maneuverability, making it particularly well-suited for use in high vibration environments where traditional wire management solutions may fall short. Additionally, its braided design provides an extra layer of protection against abrasion and wear, ensuring long-lasting performance even in the most demanding applications. For added peace of mind, flame retardant variants are available, providing an additional level of safety in potentially hazardous environments. View our braided sleeving here.

Woven Wire Loom

Renowned for its exceptional durability and versatility, woven wire loom emerges as the go-to solution for high abrasion environments where reliable wire protection is paramount. Unlike traditional split loom, woven wire loom offers superior flexibility, allowing for effortless maneuverability and easy installation even in tight spaces. Its robust construction ensures long-lasting performance, making it more durable than spiral cut loom, while still maintaining a level of flexibility that promotes seamless wire management. What sets woven wire loom apart is its unique texture – unlike braided sleeving, which often feels more plastic-like, woven wire loom boasts a fabric-like feel to the touch. This tactile quality not only enhances its aesthetic appeal but also provides a comfortable and user-friendly experience during handling and installation. Whether you’re working on automotive projects, marine applications, or industrial machinery, woven wire loom offers the perfect combination of durability, flexibility, and tactile comfort to meet your wire management needs with confidence and ease. Take a look at the variety of woven wire we offer here.

Heat Shrink Loom

Introducing loom with cutting-edge heat shrink technology, engineered to provide unparalleled protection against mechanical abrasion and wear. This advanced loom solution not only safeguards wire bundles from external hazards but also offers the added benefit of heat shrink functionality. Upon application of heat, the loom undergoes a shrinkage process, securely enveloping wire bundles and holding them in place with a firm grip. Remarkably, this loom is capable of shrinking to half its original size, ensuring a snug and protective fit for wires of various diameters. Its highly flexible nature further enhances its usability, allowing for effortless installation and maneuverability even in confined spaces. Additionally, the loom’s innovative design enables easy customization to fit specific wiring requirements – simply cut with scissors to achieve the desired length without compromising its integrity. Whether you’re tackling automotive repairs, electrical installations, or DIY projects, this heat shrink loom offers unbeatable performance and versatility, providing peace of mind and protection for your wire bundles in any application. Find our Heat Shrink Loom here.

Metal Sleeving

Crafted for optimum performance in grounding applications, this sleeving represents the pinnacle of quality and aesthetics in high-end automotive and motorcycle settings. Its sleek and sophisticated appearance adds a touch of elegance to any installation, making it the perfect choice for enthusiasts who demand both style and functionality. Available in tinned coppered and stainless steel variants, this sleeving offers versatility to suit a range of preferences and requirements. The tinned coppered version provides excellent conductivity and corrosion resistance, ensuring reliable grounding connections even in harsh environments. On the other hand, the stainless steel variant offers unparalleled durability and longevity, making it ideal for applications where resilience is paramount. Whether you’re enhancing the performance of your vehicle’s electrical system or adding a touch of sophistication to your motorcycle’s aesthetics, this sleeving delivers the perfect combination of form and function. With its exceptional quality and striking appearance, it’s the ultimate choice for discerning automotive and motorcycle enthusiasts seeking to elevate their projects to the next level. Take a look here.

High Temperature Protection (Fiberglass)

Our premium fiberglass high temp loom, meticulously crafted to withstand extreme temperatures with ease. Coated in a resilient resin material, this loom offers unparalleled heat resistance, capable of withstanding temperatures of up to 1200°F without compromising performance. For those seeking alternative high temp options, we also offer aluminized metallic and silicone jacketed sleeving, each providing unique benefits and characteristics to suit different applications. In environments where wires or cables are subjected to constant high heat conditions, such as in race cars or industrial machinery, investing in high temperature protection is essential to ensure the longevity and reliability of your electrical components. Whether you’re racing on the track or operating in demanding industrial settings, our high temp loom solutions provide the peace of mind and performance you need to tackle the toughest challenges with confidence. View our High Temperature Protection Loom here.

Asphalt Coated Fabric Loom Type

When it comes to safeguarding against moisture infiltration and abrasive chemicals, our asphalt-coated fabric loom stands as a formidable solution designed to excel in the harshest of environments. Unlike traditional split looms, this non-split variant offers comprehensive protection against external elements, ensuring the integrity of your wiring remains intact even in the most demanding conditions. Coated with a flame retardant coating, this loom not only shields against moisture and chemical corrosion but also provides an additional layer of safety in potentially hazardous settings. Its robust construction and durable coating make it exceptionally well-suited for use in industrial applications, marine environments, and automotive settings where exposure to harsh elements is inevitable. Whether you’re operating heavy machinery, navigating marine vessels, or conducting outdoor installations, our asphalt-coated fabric loom delivers the reliability and durability you need to keep your wiring protected and secure in any situation. Take a look at our variety of diameter and spool sizes here.

For more information on wire and cable loom, please contact one of our very helpful Customer Satisfaction Representatives at 1.800.654.4757 or via email at info@delcity.net .