Automotive relays come in various types to accommodate different electrical applications. Understanding these differences is crucial in selecting the right relay for your vehicle or project. Below is an overview of some of the most common types of automotive relays and their uses.

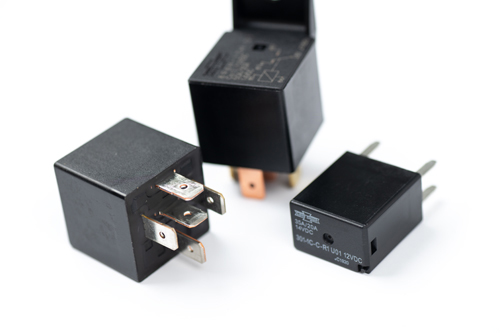

Change-Over Relays

Change-Over Relays are among the most commonly used automotive relays. These relays have five pins and can be wired in three different ways:

- Normally Open (NO): Uses pins 30 & 87.

- Normally Closed (NC): Uses pins 30 & 87a.

- Change-Over Configuration: Uses pin 30 along with both 87 & 87a.

When used as a Change-Over Relay, it switches current between two circuits, depending on whether the coil is activated (ON) or deactivated (OFF). Shop our wide selection of Picker brand Change Over Relays or Song Chuan Change Over Relays.

Normally Open Relays

While a Change-Over Relay can be wired in a Normally Open configuration, a Normally Open Relay is designed specifically for this purpose. These relays have only four pins, meaning they can only be wired in the Normally Open configuration.

Potted Relays

A Potted Relay functions like any other relay but is sealed with epoxy to create a waterproof enclosure. This makes it ideal for applications exposed to moisture or harsh environments. View our Potted Relay and learn more!

Flasher Relays

Flasher Relays control turn signals and hazard lights. They come in two main configurations:

- Two-pin Flasher: Connects to power and the light circuit.

- Three-pin Flasher: Includes an additional pin for an indicator light that signals when the flasher is active.

Some flasher relays function as circuit breakers rather than traditional relays.

Thermal (Standard) Flasher

A Thermal Flasher operates based on heat buildup. As current flows through the coil, heat is generated, eventually causing the contacts to open, stopping current flow. Once cooled, the contacts reconnect, repeating the process to create the blinking pattern for turn signals. The number of connected lights affects performance.

Electro-Mechanical Flasher

This type of flasher uses a circuit board with a capacitor, diodes, and a coil to generate the flashing effect. It offers better performance than thermal flashers and is capable of handling higher electrical loads.

LED Flasher

LED Flashers are fully electronic and controlled by a small solid-state integrated circuit (IC) board. Unlike thermal and electro-mechanical flashers, LED flashers are unaffected by the number of connected lights and are designed specifically for low-current LED lighting systems.

Wig-Wag Flashers

Also called Alternating Flashers, Wig-Wag Flashers use a solid-state circuit to alternate between two separate lamp circuits, commonly found in emergency vehicles. Our professional-grade Wig Wag Flashers use solid-state technology to ensure durability and consistent performance.

Check out all of the various Flasher Relays we have available at Del City.

Skirted Relays

Skirted Relays have an extended bottom skirt designed to seal against a socket, protecting the contacts from water and contaminants.

Time Delay Relays

Time Delay Relays allow current flow for a specified duration after power to the coil is switched off. The delay can range from 2 seconds to 3 minutes, controlled by a solid-state timing circuit with a variable resistor. A common use case is for keeping parking lights illuminated for a short period after exiting a vehicle.

Dual Open Contact Relays

Dual Open Contact Relays have five pins like a Change-Over Relay but differ by featuring two Normally Open contacts (87 & 87a), rather than one being Normally Closed. These relays are commonly used in European vehicles.

Choosing the Right Relay

Selecting the right relay depends on your electrical needs. Whether you require a waterproof Potted Relay, an LED Flasher, or a Time Delay Relay, understanding how these relays function can ensure the success of your project.

Want to learn more about how relays work? Check out our in-depth guide on How Automotive Relays Work for further insights.

For a complete selection of automotive relays, visit Del City or call 1.800.654.4757 for expert assistance.