What is a Wire Ferrule? Its basically just another way to terminate a wire based on your application. One of the most common items found in electrical applications is a wire terminal. The uses are countless, and they frequent industries such as automotive, industrial, manufacturing, marine, solar, and more. A wire ferrule, though notably not as well known as a wire terminal, is a growing product that is being used more and more every day. Already commonly used in Europe, the wire ferrule is becoming increasingly utilized throughout the globe. Even though they are growing in popularity, you might have some questions! Continue reading to find out more.

What is a wire ferrule?

A wire ferrule is crimped to the end of a stripped wire, very similar to a terminal. When it is crimped onto a stranded wire, it protects the fine strands from fraying. It is inserted into the terminal compartment and crimped onto the wire.

What is the difference between a wire ferrule and a terminal?

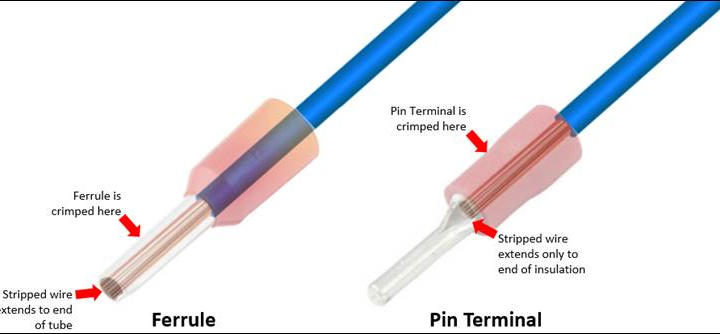

The main difference is where the wire is crimped in comparison to other terminals. A wire ferrule is crimped in the metal tube itself instead of where the insulation covers the barrel. The metal tube in which a wire ferrule is crimped does not extend into the insulation. This difference is easily seen in the appearance of both a wire ferrule and wire terminal.

What are the benefits?

They are seen in countless industries where power distribution and connections are needed. They are especially common in automotive or industrial applications and are frequently used with screw type terminal blocks. A wire ferrule provides benefits over simply inserting the bare wire strands. Boasting benefits such as no strand fraying, better contact, easier repeated insertion and removal from terminal, and strain relief; the ferrule is no stranger to connections. Many who use wire ferrules enjoy the benefits of the repeated insertion and removal to aid in long term projects.

What types of wire ferrules are available?

Del City offers insulated wire ferrules, twin insulated wire ferrules, and non-insulated ferrules. This variety ensures there is a wire ferrule for almost  every application. The insulated wire ferrules offer a larger guide for inserting the wire strand. This helps to ensure a minimum bend in tight spots. The insulation is color coded for ease of determining gauge size. A twin insulated wire ferrule provides the same benefits of insulated ferrules, but allow for the crimping of two wires. If your project does not need an insulated ferrule, non-insulated are also available. Del City also offers kits of various sizes offered in the three types of ferrules described above.

every application. The insulated wire ferrules offer a larger guide for inserting the wire strand. This helps to ensure a minimum bend in tight spots. The insulation is color coded for ease of determining gauge size. A twin insulated wire ferrule provides the same benefits of insulated ferrules, but allow for the crimping of two wires. If your project does not need an insulated ferrule, non-insulated are also available. Del City also offers kits of various sizes offered in the three types of ferrules described above.

Do I need anything else to use a wire ferrule?

There are a variety of gauge sizes and pin lengths to best fit your needs. It is ideal to know the shape of the terminal compartment of the block so that you can pick out the proper crimp tool. It is impBecause in crimp tools the main difference you would see is in the shape of the crimp, we want to be sure you have the best shape crimp for your needs. Del City recommends Rennsteig Ferrule Crimping Tools and the matching dies to be sure your ferrule is crimped properly.

There are a variety of gauge sizes and pin lengths to best fit your needs. It is ideal to know the shape of the terminal compartment of the block so that you can pick out the proper crimp tool. It is impBecause in crimp tools the main difference you would see is in the shape of the crimp, we want to be sure you have the best shape crimp for your needs. Del City recommends Rennsteig Ferrule Crimping Tools and the matching dies to be sure your ferrule is crimped properly.

See Del City’s entire wire ferrule collection here and explore what they can do for you or your business. Still have questions? Please don’t hesitate to reach out to us at info@delcity.net or at 1-800-654-4757!

Find our website here and check out our blog for more articles and videos!