When you’re wiring a system that demands reliable power delivery—whether in an automotive, marine, or industrial setting—you’ll often run into two specific cable types: battery cable and welding cable. At first glance, they might seem similar: thick copper conductors with tough insulation. But dig a little deeper, and you’ll find key differences in flexibility, strand count, insulation rating, and application suitability. Choosing the wrong one can cost you in performance, longevity, or ease of installation.

In this guide, we’ll break down how battery cable and welding cable differ, where each shines, and what to watch out for when specifying or installing.

This image shows battery cable on the top, in red and welding cable on the bottom in black.

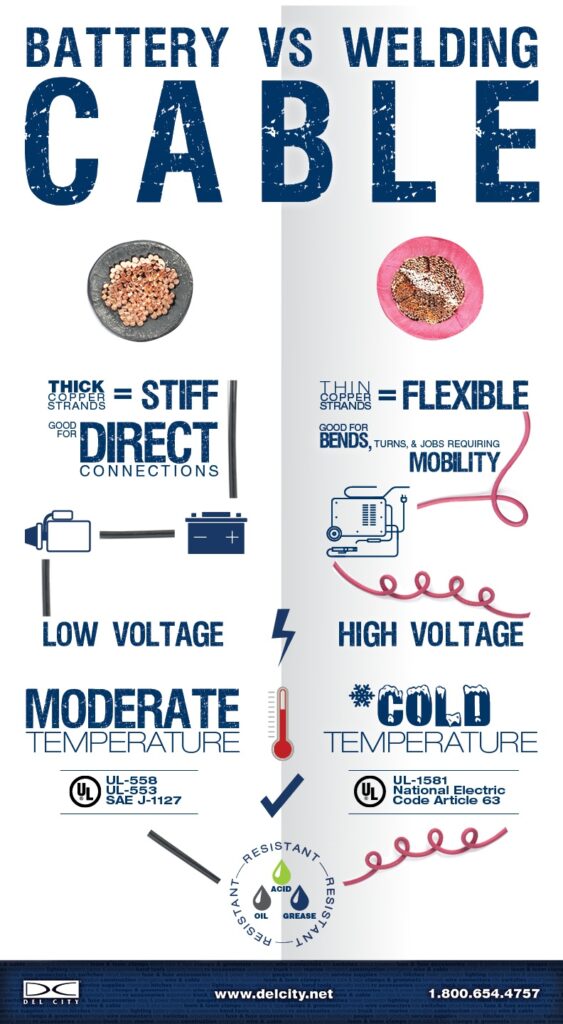

Conductor Construction & Flexibility

Battery Cable

Battery cable has thicker copper strands and fewer, more rigid wires within its insulation. That design makes it relatively stiffer and less flexible. It handles well for fixed, straightforward runs where you don’t need tight curves.

Welding Cable

Welding cable uses much finer copper strands (sometimes hundreds of them), which makes it extremely flexible. It can bend, twist, coil, and route into tight spaces more gracefully. This flexibility is one of its biggest advantages where movement or compact bending is required.

Because of its fine-strand construction, welding cable often contains more copper per foot (for the same overall gauge) than a comparably rated battery cable, giving it better conductivity and handling capacity in some scenarios.

Insulation, Ratings & Environmental Resilience

Battery Cable Insulation

Traditionally, battery cable is insulated with PVC (or similar thermoplastic), which offers protection against abrasion, weather, oil, and acids. It typically meets UL-558 and UL-553 flame-resistance standards. However, when the temperature gets low or it’s subject to repeated flexing, the insulation and conductor can stiffen and lose pliability.

Welding Cable Insulation

Welding cable is often insulated with EPDM (rubber) or comparable compounds that tolerate higher thermal cycling and exposure to harsh environments. It generally meets UL-1581 (and sometimes higher) standards. Its insulation has superior resistance to heat, flame, cuts, and repeated flex cycles compared to some battery cable options.

Voltage Range & Use Limits

Battery Cable

In practice, battery cable is commonly used up to ~60 V DC in many applications. It’s ideal when voltage range and current demands are modest and the run is fairly direct.

Welding Cable

Welding cable often supports much higher voltage ranges and greater current loads (subject to gauge and strand size). Because of its flexibility and robust insulation, it’s often chosen in high-demand builds, portable gear, or installations where flexibility and durability are key.

Ideal Applications & Use Cases

| Use Case / Scenario | Best Choice | Why |

|---|---|---|

| Simple run from battery to starter, minimal bends | Battery Cable | It’s cost-effective, durable enough, and easy to install in straightforward paths |

| Runs that require a lot of curves, routing through tight spaces | Welding Cable | Its fine-strand construction handles bends much more gracefully |

| Mobile or portable systems (lift systems, trailers, etc.) | Welding Cable | The flexibility and strain tolerance make it ideal where movement or vibration is involved |

| Environments with heat, abrasion, or vibration | Welding Cable | Insulation and conductor construction are more robust under stress |

| Low-budget, static or short runs | Battery Cable | When installation conditions are forgiving, its lower cost is a plus |

What to Watch Out For

- Over-flexing battery cable — too many bends or vibrations can fatigue the thicker strands and cause breakage over time.

- Underspec’d welding cable — choosing one with too thin insulation or strand arrangement can reduce performance.

- Termination compatibility — fine-strand welding cable may require specialized crimping or connectors designed for “flexible” cables.

- Temperature extremes — battery cable insulation can stiffen, crack, or degrade faster in very low or high temperatures.

- Voltage drop & current demands — regardless of cable type, always size properly for current load and allowable voltage drop over the length.

Conclusion

Battery cable and welding cable might appear alike at a glance, but they serve distinct roles. Battery cable excels in simple, static, short runs; welding cable dominates when flexibility, movement, tight routing, or harsher environments are involved. By understanding their differences—in conductor construction, insulation, ratings, and behavior under stress—you can make smarter wiring decisions and avoid costly mistakes.

If you’re shopping for either cable or terminations, Del City offers a wide lineup of both battery and welding cables — plus matching accessories. If you’re unsure which is right for your setup, our technical support is here to help.